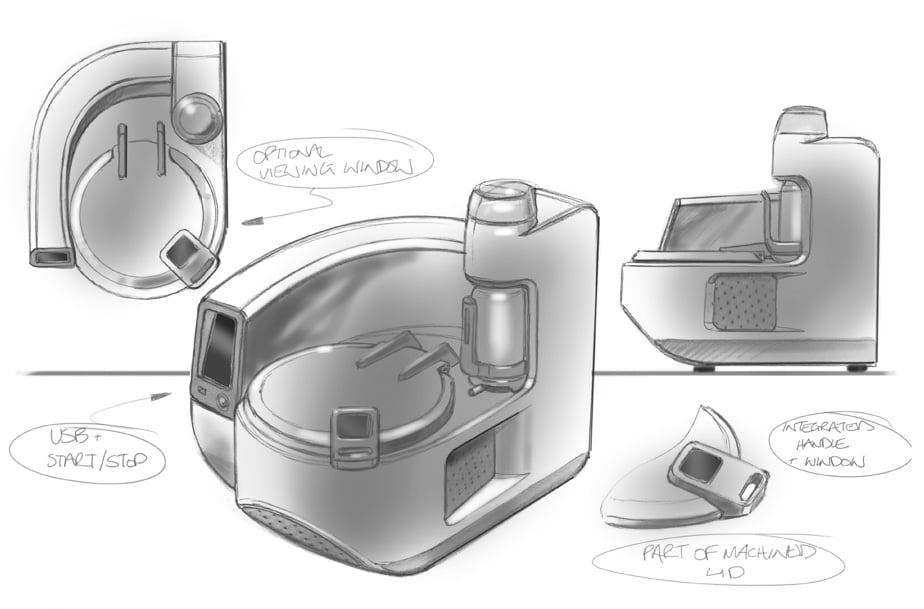

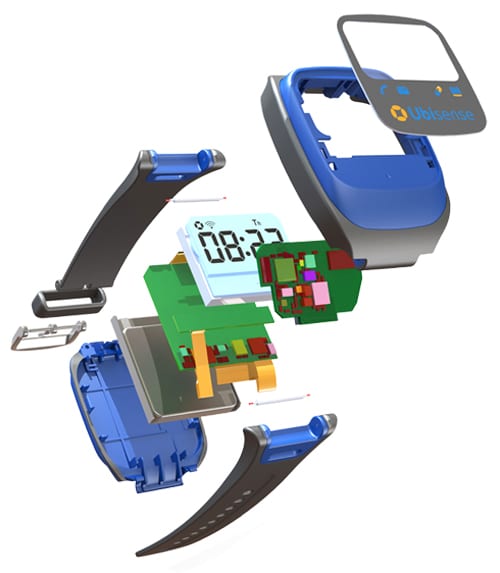

Research

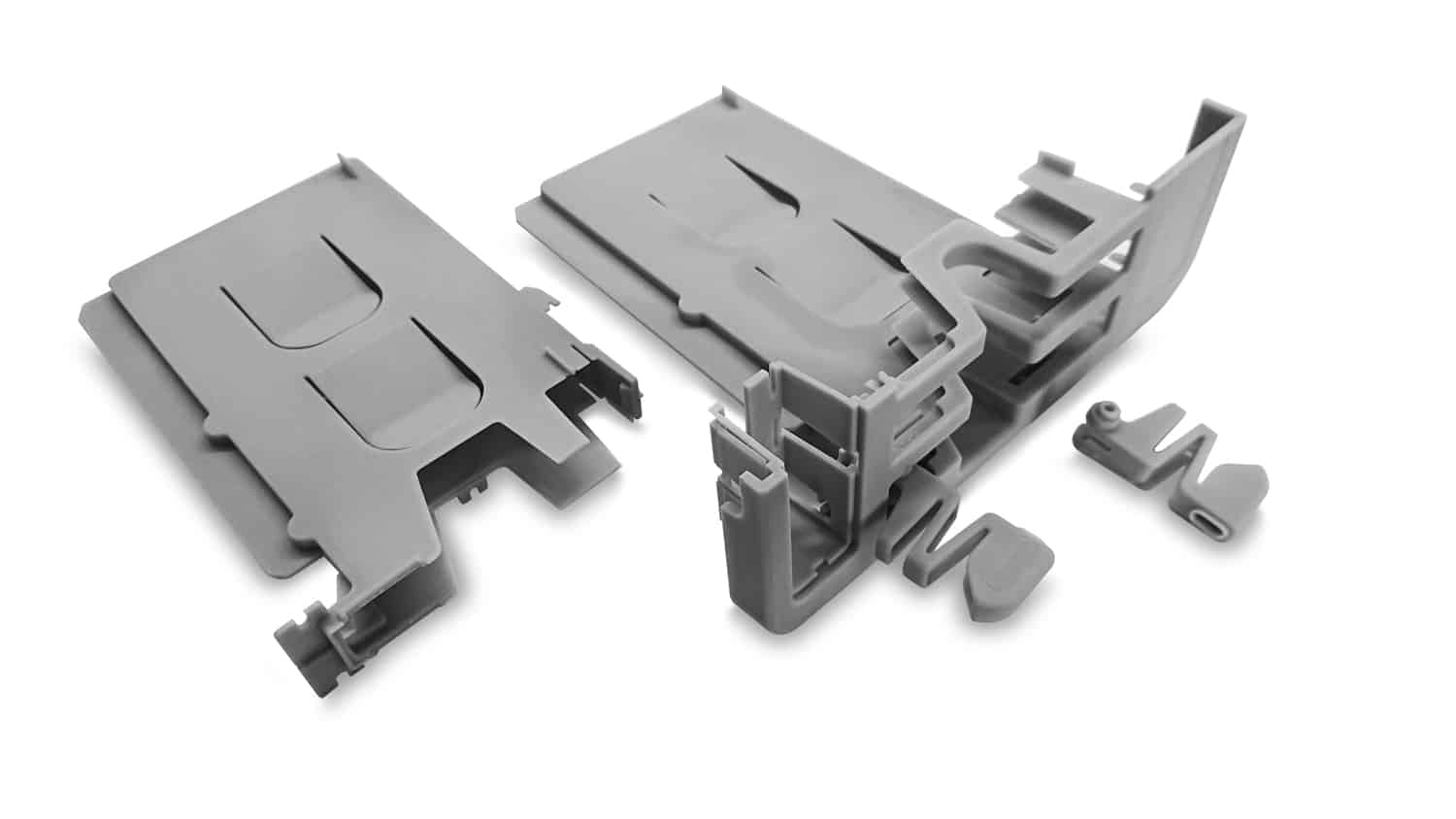

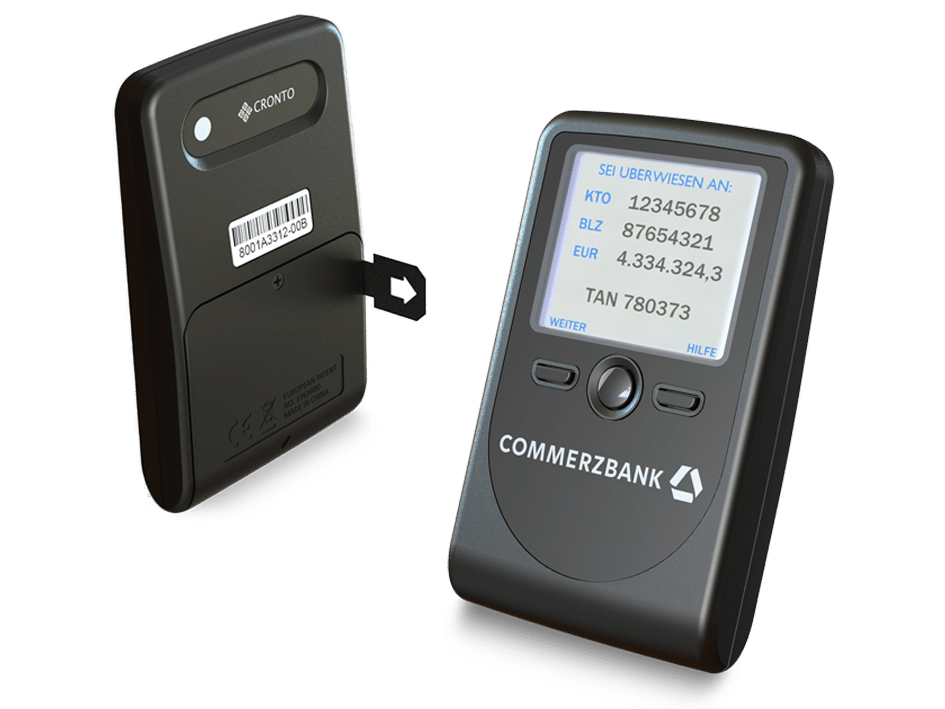

DesignEdge can work with you from the start of your product development programme. We can plan, identify milestones, key design phases and define a detailed product requirement specification. Our expertise can be used in research, competitor analysis and emerging technologies to identify development opportunities. We can access our extensive human factors and anthropometric database to optimise any ergonomics input. We know the impact of materials and production can have on the perceived value of your product in the market place and you can benefit from this knowledge.