What We Delivered

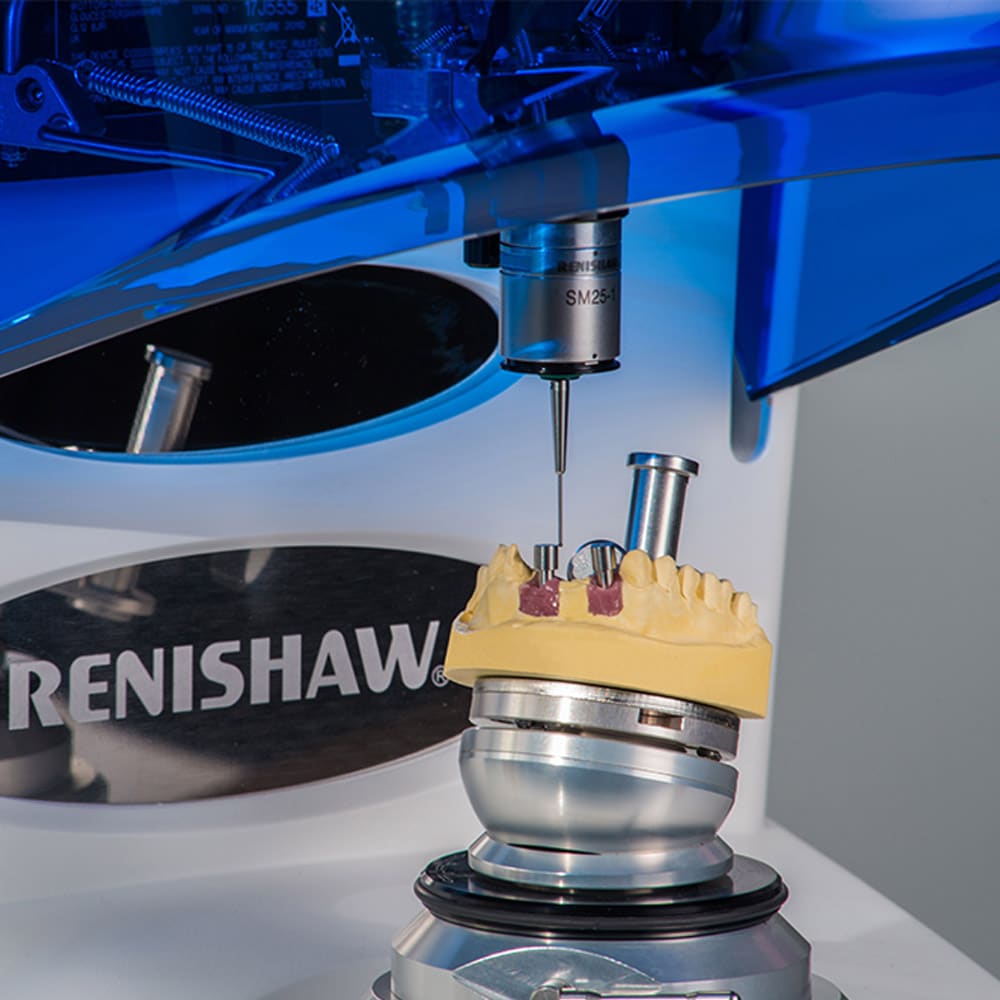

Renishaw wanted an attention-grabbing style for its latest dental scanning instruments that would make it stand out from the crowd. Renishaw’s Incise™ dental milling system will enable laboratories to manufacture zirconia frameworks in-house. The scanning machine creates 3D computer models used in the manufacture of dental crowns and bridges.

Result

DesignEdge designed a practical and affordable dental product with great visual impact within a sculptural form factor. The product design incorporates contact scanning technology for use with both the dental scanning and machining options and an accessory tray for storing scanning probes. With high accuracy tested to ISO 10360-4, the dental scanner achieves precision performance.

“The product utilises patented precision measurement technology and is aimed at the high-end dental CADCAM market, the aesthetics needed to reflect this as a ground breaking product. It was the look of the product that drew visitors to the stand at its launch in Cologne. Customers found it appealing and eye catching and its design became quite a talking point. When Renishaw began developing the product, design was high on the list of requirements. We wanted a design that brought attention grabbing aesthetics to the product.”

Bryan AustinGeneral Manager, Renishaw Dental Products

Dental Systems Product Design

Exceptional accuracy in a compact, lightweight package

DesignEdge worked alongside Renishaw engineering to design the dental scanner and created a fluidic form and a sculptured aesthetic, the result achieves superior accuracy through the use of Renishaw's contact scanning technology which has been used in thousands of measurement applications worldwide, including critical applications such as aerospace engine parts. A dental impression can be scanned to within an accuracy of 10 microns which is vanishingly small, put into context a human hair is on average 50 microns wide and some bacteria are just 10 microns long.

Patented non-cartesian mechanism

Unlike conventional designs, this provides a lightweight and cost-effective structure that enables high-accuracy processing in a compact device. This means that even the smallest lab can accommodate a scanner. See our product deign portfolio for other successful industrial and medical product designs.