What We Delivered

Result

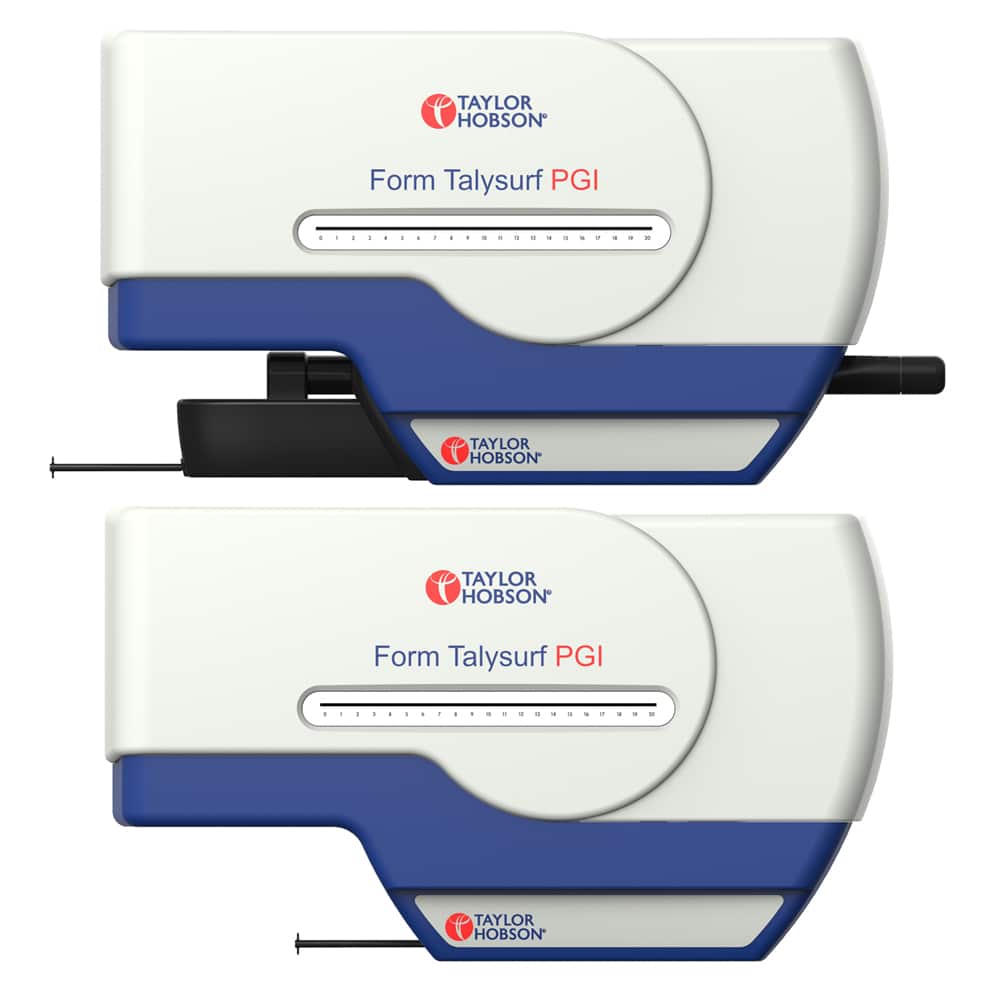

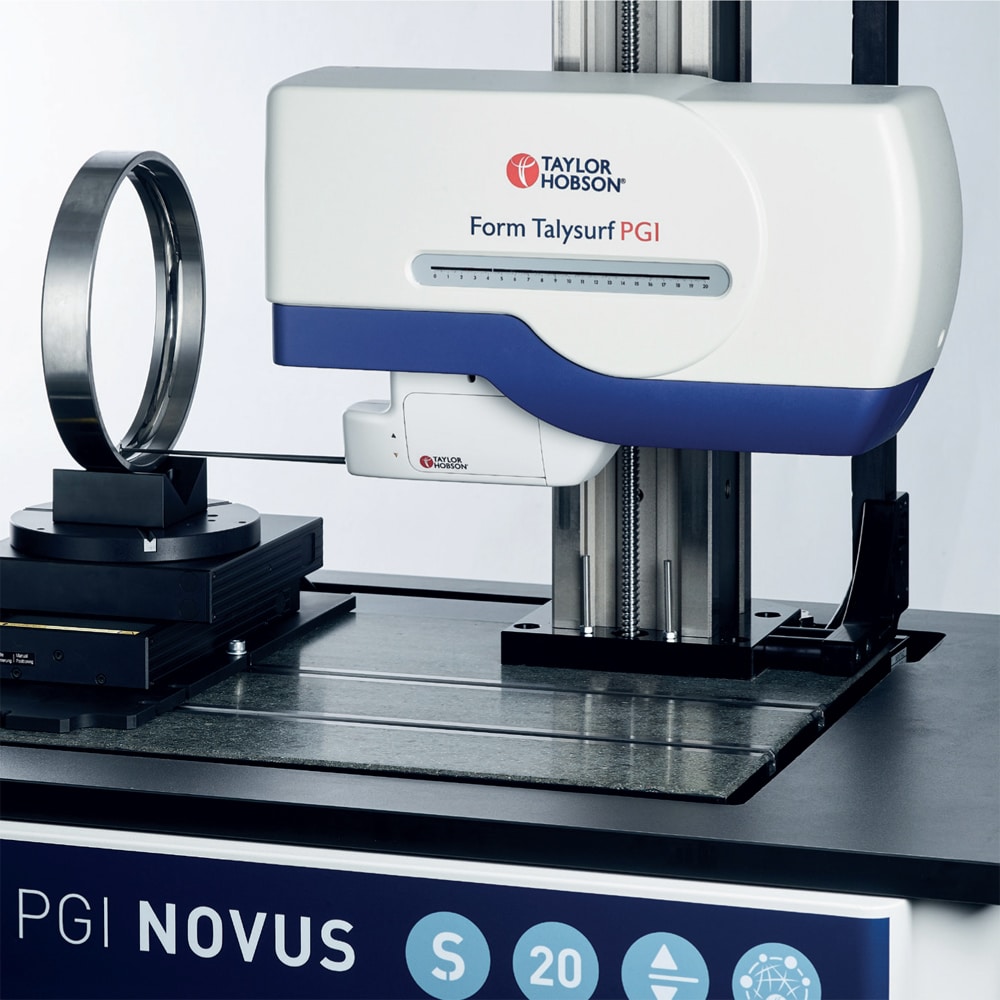

Our design team produced a visually exciting range of instrumentation designs, exploring strong surface geometry and bold 2-tone colour combinations, at the same time integrating mechanical and geometric constraints, ergonomics, internal component architecture, serviceability and optimum low cost manufacturing processes. The product design aesthetic develops and enhances the Taylor Hobson branding to the next level, reinforcing its reputation for well thought out, reliable and ultra-precise measurement instrumentation.

“We have worked with Design Edge and Bruce for many years on several projects – a good business to do business with!”

Dr Bob BennettTechnical Director

Advanced industrial product design

Advanced Surface Finish, Contour, 3D and Diameter Measuring Equipment

High impact design for metrology instrumentation

The ultimate measuring accuracy for large-scale surface profiling with unrivalled accuracy at the submicron range. The Talysurf® PGI NOVUS represents a significant step forward for measurement speed and accuracy for complex shapes.